| front |1 |2 |3 |4 |5 |6 |7 |8 |9 |10 |11 |12 |13 |14 |15 |16 |17 |18 |19 |20 |21 |22 |23 |24 |25 |26 |27 |28 |29 |30 |31 |32 |33 |34 |35 |36 |37 |38 |review |

|

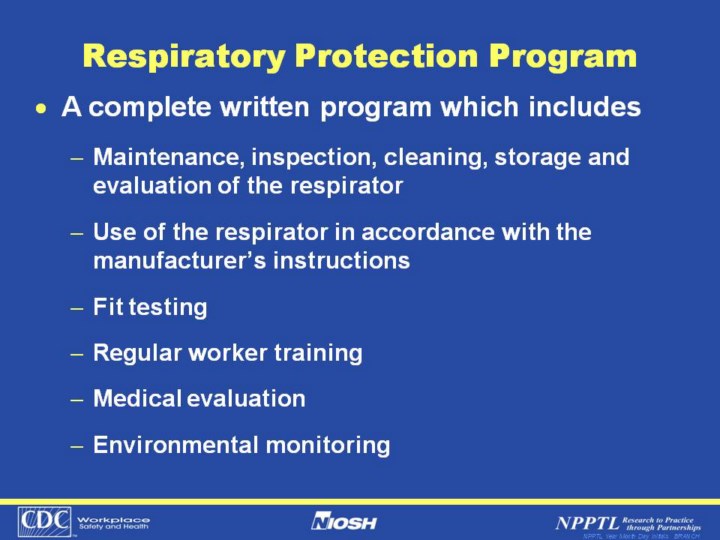

Respiratory Protection Programs Workplaces, where it has been determined that respirators are used, must have a complete written program and documented specifics which includes: - The maintenance, inspection, cleaning, storage and evaluation of the respirators. - Use of the respirator in accordance with the manufacturer’s instructions. - Fit testing protocols and test results. - Regular worker training. - Medical evaluations of employees. - Environmental monitoring.

Considerations:

- Workers are not exposed to a single unvarying concentration of a hazardous substance; rather, individual exposures may vary throughout the workshift and between days. The highest anticipated concentration should therefore be used to compute the required protection factor for each respirator wearer.

- Qualitative or quantitative fit tests must be provided to ensure that the tight fitting facepiece respirator fits the individual. Employees must pass a fit test with the exact model and size that they will wear in the workplace.

- Respirators with tight-fitting facepieces should not be used when facial scars, deformities, or facial hair interfere with the face seal.

- Respirators used in the workplace must be certified by NIOSH. A list of certified respirators can be found at: http://www.cdc.gov/niosh/npptl/topics/respirators/cel/

- OSHA Protection Standard, 29 Code of Federal Regulations (CFR), Part 1910.134 provides guidance on respiratory protection for those respirators used in General Industry. Detailed information on respirator programs can be accessed at: http://www.osha.gov/SLTC/etools/respiratory In addition, the OSHA Small Entity Compliance Guide, provides procedures and checklists that can help small businesses comply with the respirator standards. This information can be accessed at: http://www.osha.gov/Publications/SECG RPS/secgrev-current.pdf |