|

|

Soft Materials and Rheology Group Research Most of this research is supported by the Air Force Office of Scientific Research (AFOSR). Our interest in natural and synthetic

papillae is closely linked to a broader interest in buckling

phenomena and elastic instabilities. Simulations Simulating elastic instabilities is a significant challenge:

such instabilities are accompanied by symmetry breaking, large changes in

deformation, and high computational requirements. Of particular interest are

situations in which eigenvalue analysis, a basic

tool to predict buckling modes, does not successfully predict the observed

buckling modes. We are developing a new approach of applying random

perturbations and loading a structure in a step-by-step fashion. This allows

the instability – with the right mode – to “emerge”

without imposing any systematic perturbation. Fig. 1 illustrates how this

method is applied to the famous “Lame’ problem” where an

annular sheet under radial tension develops radial wrinkles.

Fig. 1: Left: A quarter model of a thin annular sheet with

random perturbations of modulus of 5% amplitude. The tension at the periphery

is fixed, whereas the inner tension is ramped up gradually. Right:

Corresponding height profile showing radial buckles. Swelling-induced

fold formation Crosslinked polymers cannot dissolve, but can swell strongly when

exposed to a good solvent. We discovered that when a thin film of polymer

weakly bound to a substrate is exposed to a drop of solvent, the swelling

induces the formation of permanent folds (Fig. 2). The mechanism of this fold

formation is a multi-step process: first the swelling region of the polymer

develops a severe compressive stress and undergoes buckle delamination off

the surface. Second, the delaminated region grows into a sharp, tall fold.

Finally, upon evaporation of the solvent, the fold does not relax back, but

becomes permanent. This is not a wrinkle-to-fold transition (in which

sinusoidal precursor wrinkles turn into folds). Instead, the film goes

directly from a flat to a folded state. We are now examining methods to the

location and shaoe of folds.

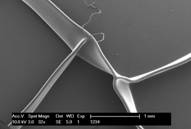

Fig. 2: Left: A drop of toluene swelling a PDMS film and

forming folds. Right. SEM image of folds after evaporation of solvent. Images

are from Velankar, Lai and Vaia, ACS App. Mat. Int.,

4, 24-29, 2012. Download.

See two videos of

the fold formation process. Thin

film buckling on liquid substrates Our lab has a long-standing interest in

compatibilizers added to blends of immiscible polymers.

Compatibilizers are block copolymers of various architectures which are

adsorb at the interface between immiscible homopolymers and strongly affect

the mechanical properties of the interface. Yet, quantitatively measuring

these mechanical properties is difficult since the compatibilizer films are

only a few nm thick and are inextricably bound to the surrounding –

very viscous – homopolymers. We seek to use buckling phenomena to

obtain the mechanical properties. The basic idea is to apply a compressive

stress on the interface to induce interfacial buckling and use the buckling

characteristics to back out the mechanical properties of the interface. We

are presently validating our methods using plastic films floating on the

surface of viscous polymer fluids (Fig.3). Once successful, this approach

will be applied to compatibilizers.

Fig. 3: Thin plastic film floating on a liquid buckles due to

compression. The buckling wavelength is related to the modulus of the film. Questions, Suggestions,

Comments? Send e-mail to velankar@pitt.edu

|

Current projects Interfacially-active

particles Natural and

synthetic papillae

|